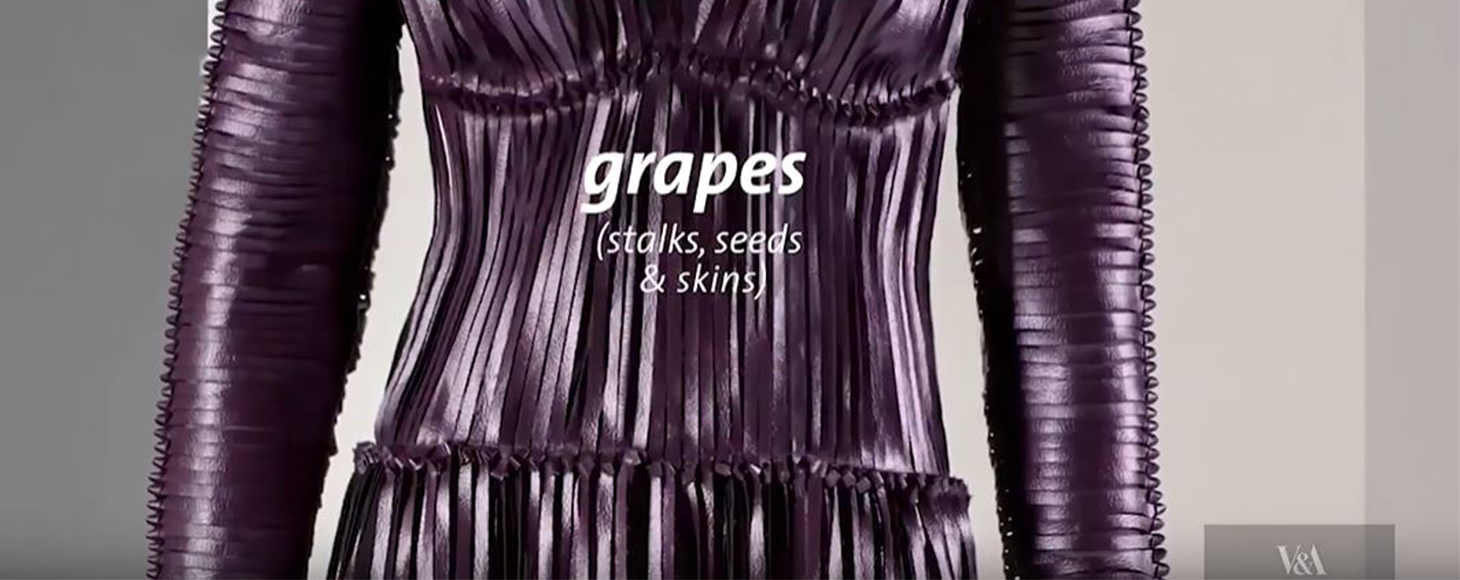

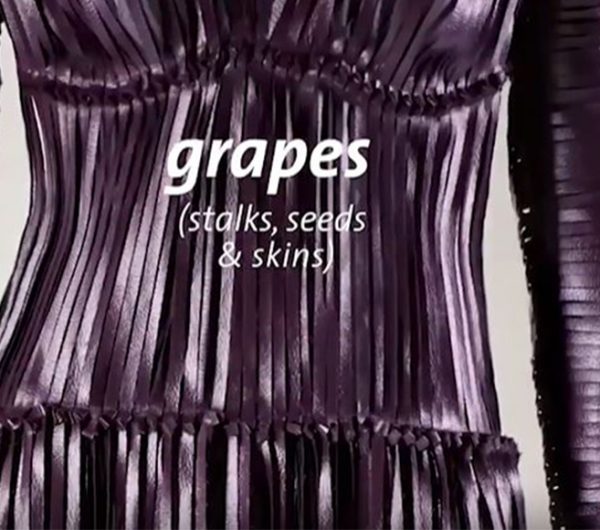

Challenge 6: Rethinking material resources

Industry Lead: Keracol

Microfibre pollution from synthetic textiles accounts for over one third of plastics in the open ocean. With growing public and consumer awareness, the environmental incentive for rethinking alternative material resources could not be more stark.

Meanwhile, the UK food and drink manufacturing industry produces almost 2 million tonnes of waste per annum – the dairy industry being the largest generator of such waste. Much of this waste is inevitable, for example by-products of cheese production, and could be reimagined as resource.

While alternative material development for fashion and textiles may be considered relatively nascent, pioneering chemists in the 19th and 20th Century developed to semi-commercial scale a range of largely-forgotten Regenerated Protein Fibres (RPFs) – including those derived from milk, egg and soy.

Early research focusing on fungi, nettle, hemp and seaweed was also relatively advanced, and emergent technologies have received renewed interest in recent decades. The final technical barriers to widespread exploitation, which halted RPF and non-protein-based fibre innovation in the early 20th Century, can now be overcome.

Recent publications:

- ‘The Potential for Regenerated Protein Fibres within a Circular Economy: Lessons from the Past Can Inform Sustainable Innovation in the Textiles Industry’, Sustainability, 2021, https://doi.org/10.3390/su13042328

- ‘From Clothing Rations to Fast Fashion: Utilising Regenerated Protein Fibres to Alleviate Pressures on Mass Production’, Energies, 2021, https://doi.org/10.3390/en14185654